Most NDT Companies Rent Their Gear. We Build Ours.

99% of NDT companies either:

- Use third-party equipment for their inspections.

- Sell inspection equipment to others.

Cost Savings – In-house innovation keeps projects efficient.

Speed – Purpose-built tools mean faster inspections and less downtime.

Accuracy – Engineered for maximum sensitivity and reliability.

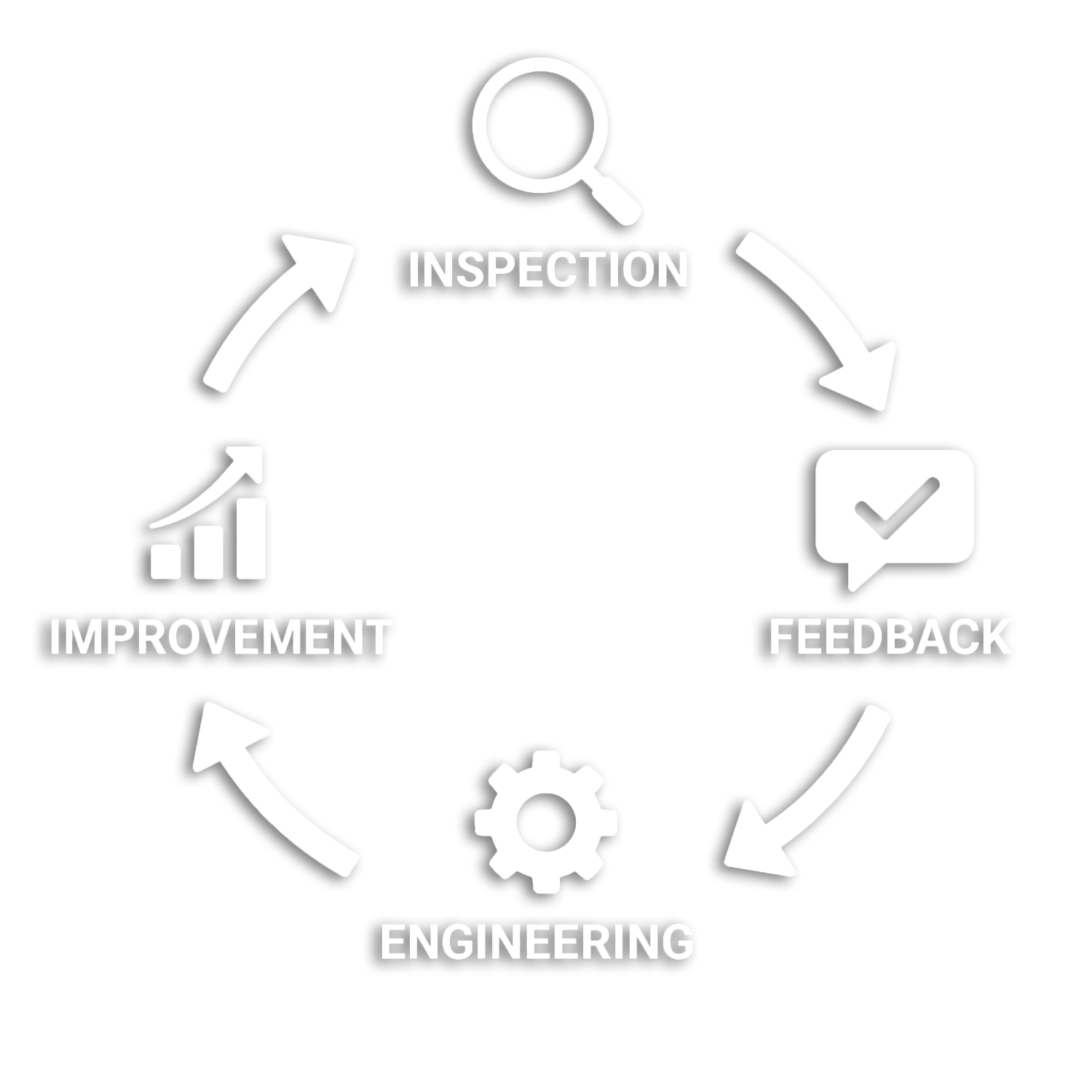

Every Job Makes Our Equipment Better.

- Our inspectors and engineers work in constant feedback loops—every insight from the field drives improvements in our tools. This ensures our technology stays ahead of industry standards and your inspections get the benefit of continuous innovation.

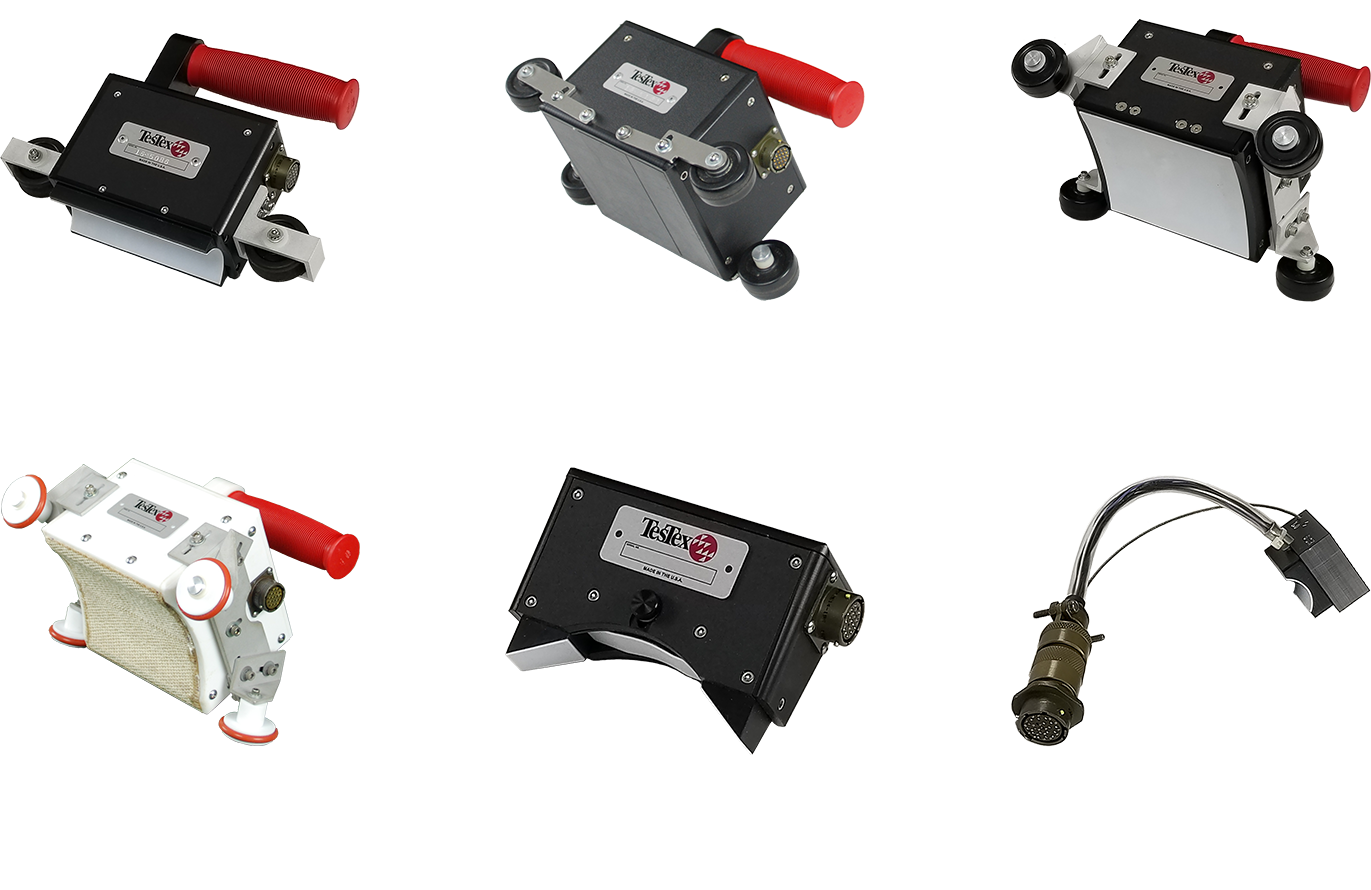

Advanced Inspection Methods, All In-House.

- LFET – Low Frequency Electromagnetic Technique for rapid flaw detection.

- RFET – Remote Field Electromagnetic Technique for tubing inspections.

- BFET – Balanced Field Electromagnetic Technique for weld crack detection.

- ECT – Eddy Current Technique Tubular inspections.

- PAUT – Phased Array Ultrasonic Testing for detailed imaging.

- And more…