- TesTex Inc. has a wide variety of services available to Upstream Oil Providers. These services utilize the following techniques:

- Low Frequency Electromagnetic Technique

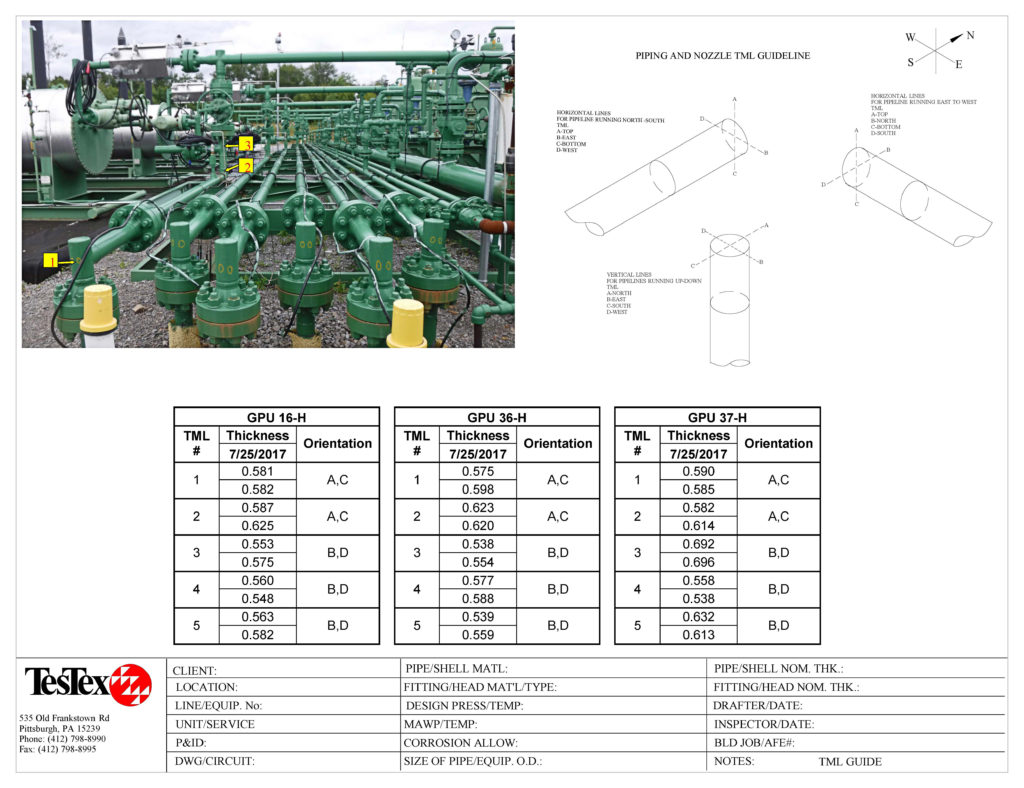

- Ultrasonic Thickness Measurement

- Mag particle & Dye Penetrant

- Balanced Field Electromagnetic Technique

Upsteam Oil & Gas

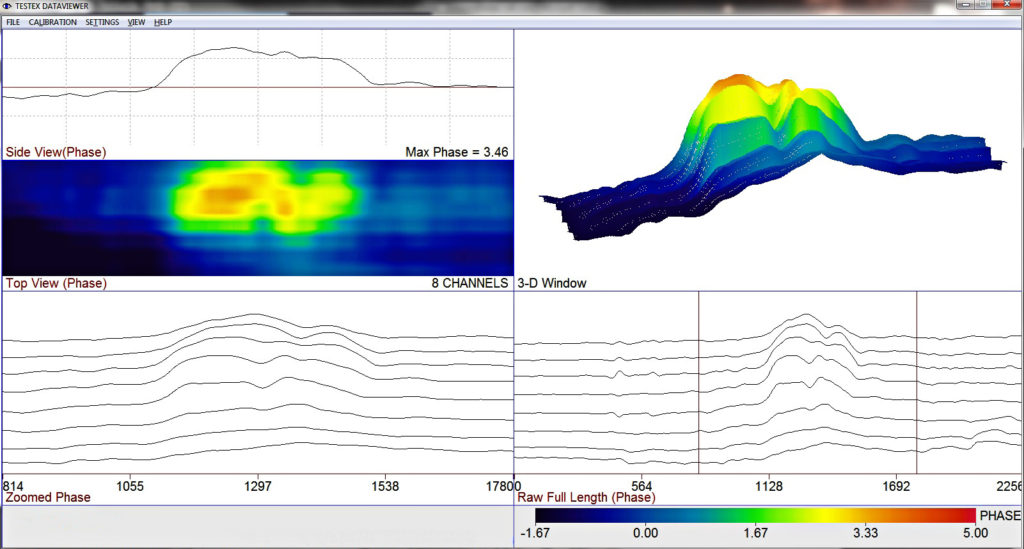

- With our proprietary Low Frequency Electromagnetic Technique (LFET), we offer efficient scanning of tank walls, tank floors, and pipelines to identify potential issues. This enables us to quickly pinpoint areas that require Ultrasonic Thickness (UT) measurements. Unlike other techniques, our UT measurements accurately assess wall loss without the need for extensive preparation work, saving time and effort.

- Falcon System Floor Scanners are used to inspect tank floors

- Falcon Hand Scanners are used to inspect tank walls

- The Line CAT and Line CAT Plus Systems are used to inspect pipelines

- Viper crawler system can be outfitted with UT or LFET technology to scan hard to reach surfaces without scaffolding

- Our inspections can be conducted in remote areas using three-person crews and portable power sources. This strategic approach enables us to swiftly deploy our teams to the often distant locations where these tanks and pipelines are typically found.

Low Frequency Electromagnetic Technique and Ultrasonic Thickness Measurement

We employ advanced techniques such as Magnetic Particle and Dye Penetrant testing to identify weld cracking in critical areas of the tank, including manhole welds, plate welds, and structural add-ons like D-rings or lift points. Our thorough inspection process includes visual assessments of the site to identify any additional potential issues, and customers will receive a detailed report with accompanying pictures highlighting any areas of concern.

In addition, our expertise extends to the use of Balanced Field Electromagnetic Technique (BFET) for detecting welding cracks. This technology is particularly effective for small welded areas such as socket welds, providing a safer alternative to X-ray testing.

Mag Particle / Dye Penetrant

Clicking "Quote" will add the item to a temporary cart and prompt you to register/login. To view the items in this cart or send us an email requesting a quote, please complete the registration process or login.

| Description | Quantity | Add to |

|---|---|---|

| Upstream Oil & Gas Inspection Services | ||

| Falcon System Floor Scanners | ||

| Falcon Hand Scanners | ||

| Line CAT System | ||

| Line CAT Plus System | ||

| Dye Penetrant Inspection Services | ||

| Magnetic Particle Inspection Services | ||

| Triton II BFET System |