Above Ground Storage Tank Inspections

-

TesTex offers a range of tank floor scanning services, complementing our API 653 inspections. Our advanced scanning systems, such as the Falcon Mark II and Falcon S Series, enable comprehensive inspections of tank floors. For tank welds, we utilize the Triton II BFET system.

Unlike Magnetic Flux Leakage (MFL) equipment that relies on permanent magnets, our LFET technology is lightweight, portable, and does not require magnets. The Falcon Mark II excels in scanning through coatings and tightly-bonded, uniform scale. It effectively detects topside and underside corrosion on floor plates. Identified areas are marked and further verified using ultrasonics to ensure accuracy. Trust TesTex for reliable and efficient tank floor inspections.

Tank Floor Inspections with the Falcon S Series

-

The Falcon S Series incorporates advanced technology similar to our Mag Wave system, introducing Eddy Current accuracy to ferrous plates. Leveraging the remarkable sensitivity of eddy current, this scanner excels at detecting and quantifying top side/bottom side pitting, localized wall loss, and even cracks. Notably, the Falcon S Series possesses the remarkable capability to scan through non-metallic coatings up to 0.5 inches (12mm) in thickness. Experience the power of the Falcon S Series for precise and efficient inspection of ferrous plates.

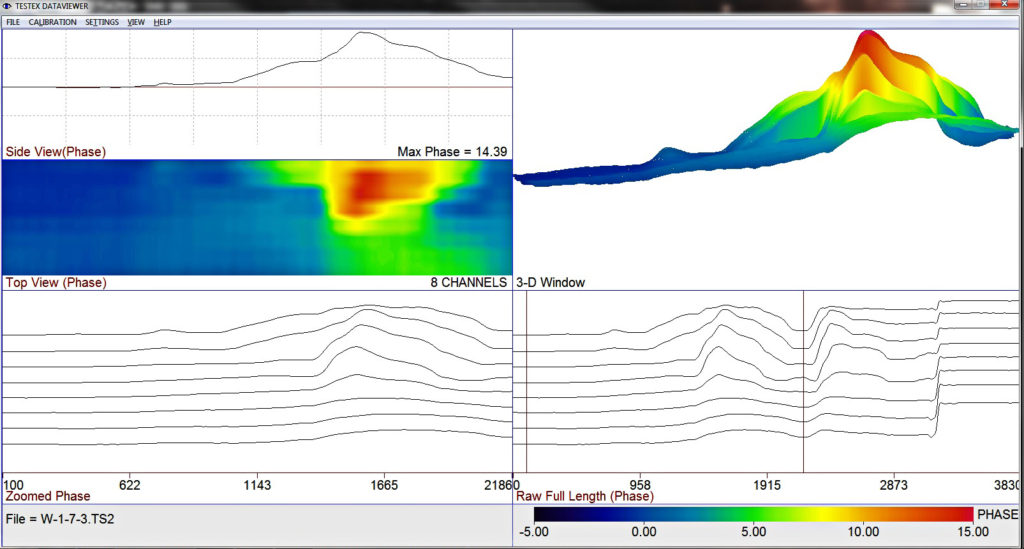

Waveform shows a corrosion cell on a above ground storage tank

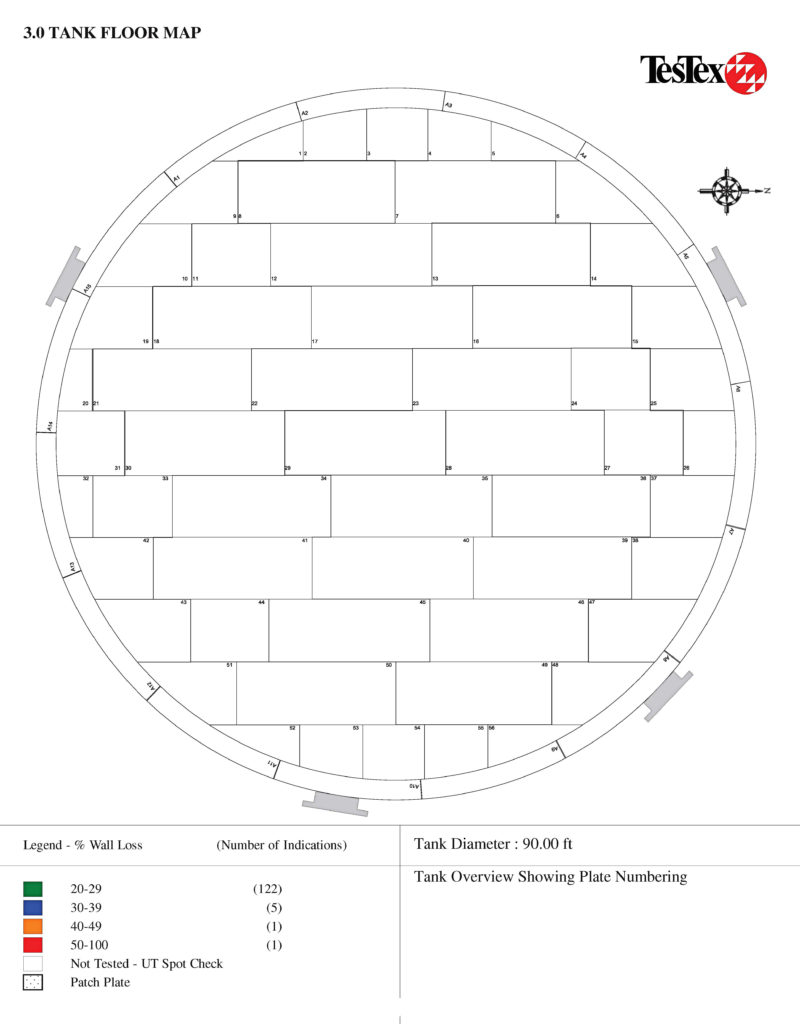

Waveform shows a corrosion cell on a above ground storage tank Tank floor map generated with mapping software

Tank floor map generated with mapping softwareTank Inspection Supporting Technologies

-

TesTex goes beyond traditional inspections by offering the compact Falcon JR and Falcon S hand scanners. Built upon the reputable technologies of their larger counterparts, these scanners allow for thorough examinations of hard-to-reach areas such as those surrounding support legs, sumps, buckled annular plates, or under heating coils.

For comprehensive weld inspections, the Triton II BFET is deployed to detect both surface and sub-surface cracks. In addition, TesTex provides alternative inspection methods like magnetic particle inspections and vacuum box testing.

Introducing the TesTex Viper Crawler System, a highly efficient solution for ultrasonic (UT) scans on ferrous above-ground storage tanks. This innovative crawler system offers a more cost-effective alternative to scaffolding, ensuring thorough inspections without compromising on quality.

The results are presented in a detailed inspection report, and our inspections can include:

- Floor scans using Low Frequency Electromagnetic Technique (LFET) and/or Saturation Low Frequency Eddy Current scanners and hand scanners to detect topside and bottom side corrosion

- Scan through coatings and tightly bonded scale

- Shell visual and or ultrasonic thickness inspections via remote crawler

- Foundation settlement assessments to detect various forms of tank foundation movement

- Weld inspection via magnetic particle, electromagnetic techniques, liquid penetrant, UT weld inspection and vacuum testing techniques

- Visual inspection of the tank bund wall and bund area

- RBI (Risk Based Inspection) & site audits for determining inspection intervals & inspection work scopes

- Click here to see our Tank Inspection Services video.

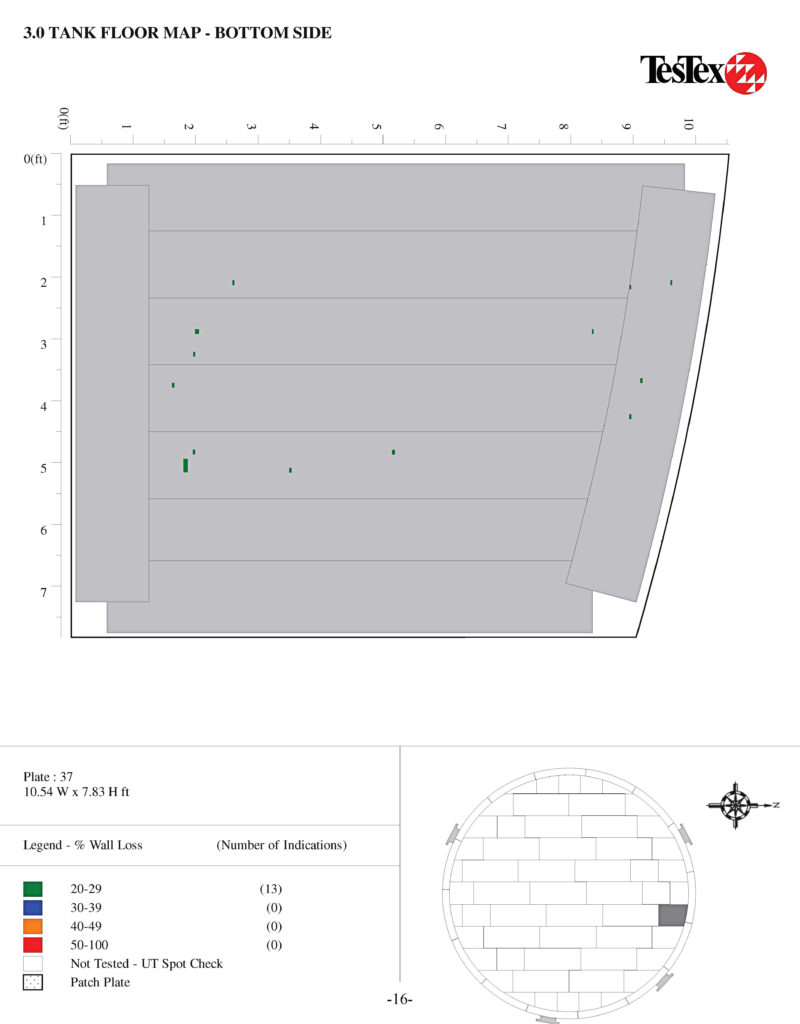

Tank floor plate showing areas of pitting

Tank floor plate showing areas of pittingClicking "Quote" will add the item to a temporary cart and prompt you to register/login. To view the items in this cart or send us an email requesting a quote, please complete the registration process or login.

| Description | Quantity | Add to |

|---|---|---|

| Above Ground Storage Tank Inspection Services | ||

| API 653 Inspection Services | ||

| Falcon Mark II | ||

| Falcon S Series System | ||

| Triton II BFET System |