Since its establishment in 1987, TesTex has been dedicated to advancing non-destructive testing (NDT) methods, with a primary focus on electromagnetics. Our initial research and development project for Bettis Atomic Labs and the United States Nuclear Navy involved the creation of inspection technology for magnetic Heat Exchanger Tubes. This groundbreaking technology enabled the detection and quantification of wall thinning and pitting without the need for a secondary inspection method. The success of the Bettis project led to the development of the Remote Field Electromagnetic Technique (RFET), which revolutionized tubing inspection by introducing portable computers for data display and analysis.

Throughout the 1990s, TesTex continued to refine RFET methods through collaboration with various industries, including petroleum refining, chemical, petrochemical, power, pulp and paper, and steel. These collaborative efforts resulted in the development of the state-of-the-art TesTex Multi-Channel RFET, which represents the pinnacle of RFET technology today.

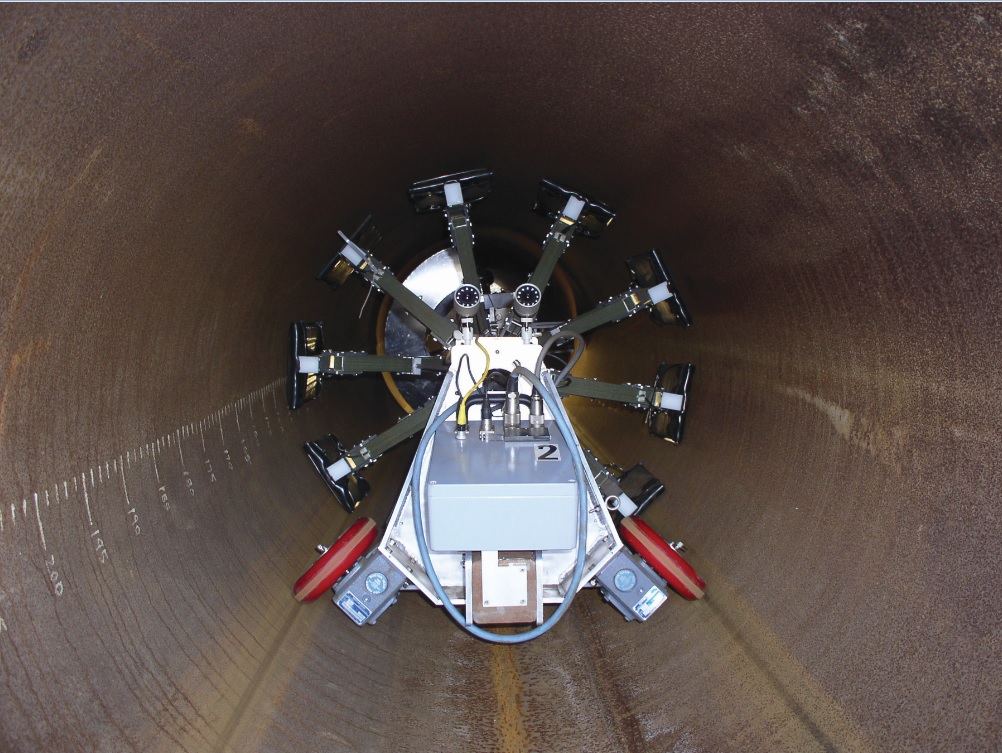

In 1992, TesTex expanded its expertise to include the Low Frequency Electromagnetic Technique (LFET) for inspecting above ground storage tanks (AGSTs). Since then, LFET methods have been successfully applied to various product lines and settings, including pipeline, pressure vessel, boiler waterwall, superheater, reheater scanning, as well as large diameter pipe inspections from the outer diameter (OD).

Research and Development

TesTex is at the forefront of Crack Detection technology with the introduction of the Balanced Field Electromagnetic Technique. This advanced technique allows for the detection of surface and sub-surface cracking in both magnetic and non-magnetic metals. Our field-deployed TesTex Triton Crack Detection Systems have the capability to detect cracks within 1/8″ of the surface, and we are continuously pushing the boundaries with new prototype sensors that can detect cracks within 3/8″ of the surface.

To stay ahead of the curve, TesTex maintains a strong focus on research and development. Our dedicated team of seven full-time researchers brings expertise in digital design, mechanical innovation, software programming, system integration, and sensor development. We actively seek input from industrial customers, trade groups, and our own market intelligence to drive our R&D efforts.

In our pursuit of excellence, TesTex consistently incorporates the latest advancements in digital signal processing (DSP) chips, field programmable gate arrays (FPGA), software algorithms, and automation. These cutting-edge technologies enable us to deliver state-of-the-art systems for Electromagnetic Non-Destructive Evaluation (NDE).

- Electric Power Research Institute (EPRI)

- Gas Research Institute (GRI)

- Bettis Atomic Power Laboratory

- Innovation Works

- ExxonMobil

- Timken Company

- Western Pennsylvania Advanced Technology Center

- Ben Franklin Advanced Technology Center

- BPAmoco

TesTex is involved with applied R&D for the following organizations:

Clicking "Quote" will add the item to a temporary cart and prompt you to register/login. To view the items in this cart or send us an email requesting a quote, please complete the registration process or login.

| Description | Quantity | Add to |

|---|---|---|

| Research and Development Services |