HRSG Inspection Tools

(Heat Recovery Steam Generators)

- The compact design of HRSGs provide TesTex a unique opportunity to innovate new tools for Non-Destructive Testing. In conjunction with Electric Power Research Institute (EPRI), we have designed testing devices utilizing proven innovative electromagnetic techniques.

- Low Frequency electromagnetic Technique (LFET) is used to test the leading and trailing edge of accessible HRSG finned tubes to detect pitting and wall thinning

- For the inspection of tube to header welds for cracking, we utilize a specially designed “Claw” system outfitted with Balanced Field Electromagnetic Technique (BFET) sensors

- For internal tube inspections, we have an advanced Remote Field Electromagnetic Technique (RFET) probe coupled with a video camera that works with the Internal Access Tool

- We also perform Ultrasonic Thickness Testing on the un-finned sections of the HRSG tubes and pipe elbows for the detection of Flow Accelerated Corrosion

- We also offer borescope inspections of select tubes with access through the steam drum

- Our technology has been featured many times on CCJ online:

- HRSG Showcase →

- Golden Nuggets from the CCJ forum →

- New tools for HRSG inspection →

- Tube to header weld cracking →

- NDT on HRSG prevents forced outages →

- New tools for locating pitting etc.. →

Balanced Field Electromagnetic Technique (BFET)

Inspection of HRSG Tube to Header Weld

- We adapted the Balanced Field Electromagnetic Technique (BFET) to inspect the tube to header welds in HRSG units for cracking. The BFET sensors and cameras are placed on the welds using a C-clamp housing called the “Claw” that attaches to the tube.

- View the Claw tool

- Once attached, the Claw moves circumferentially around the weld to detect cracking, lack of fusion, porosity and other weld defects

- No surface preparation is needed to perform the Claw inspection

- A two man team can examine up to 200 tube to header welds in a shift

- Used for inspection of tube diameters from 1.5″ (38mm) to 3″ (76.2mm)

- Cameras are used to show contour of weld to help in analyzing the BFET data

Claw positioned to inspect tube to header weld

LFET scanning performed from outside of finned tubes

Low Frequency Electromagnetic Technique (LFET)

Inspection of HRSG Finned Tubes

- The Low Frequency electromagnetic Technique can detect and quantify wall thinning on HRSG finned tubes from the outside surface through the fins. The LFET scanner moves along the tube as it measures the strength of the return signal that is emitted into the tube by the scanner’s exciter coil.

- View the LFET HRSG Tool

- Can detect both localized wall losses such as pitting and flow accelerated corrosion in the base tube

- No surface preparation is needed to perform the LFET inspection

- A two man team can examine up to 1500 linear feet (460m) in a shift

Remote Field Electromagnetic Technique (RFET)

Inspection of HRSG Finned Tubes

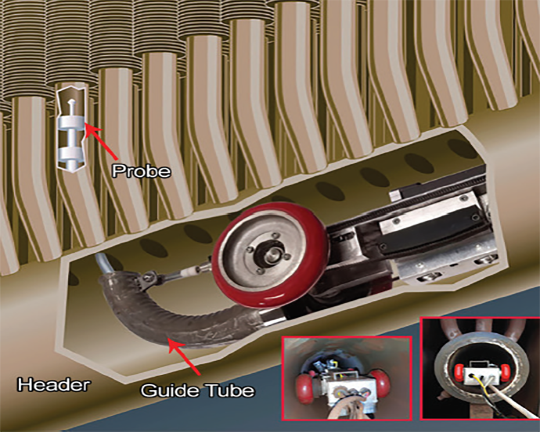

- We have developed a crawler called the “Internal access Tool” (IAT) that is inserted inside a header after the plant removes the end cap. A small hole is cut into the casing to provide access to the header. Once the IAT is inserted in the header, it pushes a RFET probe equipped with a camera up the length of the tubes recording video and detecting changes in the tube’s wall thickness.

- View the Internal Access Tool

- The IAT is remotely driven by a technician

- The RFET probe is able to test through modest scale buildup

- Video and RFET data are encoded to provide the elevation of any flaws found

- The IAT is able to test all the tubes in a header in 3-4 shifts

- Manual inspection of select tubes can be accomplished by cutting an opening in the top or bottom of the header

HRSG internal access tool in header examining tubes

Clicking "Quote" will add the item to a temporary cart and prompt you to register/login. To view the items in this cart or send us an email requesting a quote, please complete the registration process or login.

| Description | Quantity | Add to |

|---|---|---|

| HRSG Inspection Services |