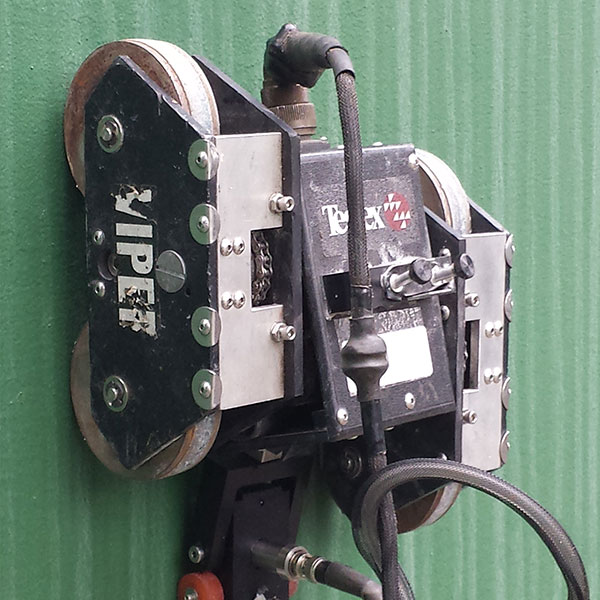

- Strong permanent magnetic wheels hold the system to the magnetic surface even through several layers of paint

- Long lasting, high torque planetary gear mechanism for travel over welds and patch plates

- Inspect tanks, piping, pressure vessels, duct work, etc.

- Optional encoder for distance processing

- Zero turn-radius for fast and accurate maneuverability

- Offset wheel design allows maximum surface contact at all times

- Operates at variable speeds through a handheld controller

- Hand held controller

- Motor control electronics box

- 100 ft. (30.5m) umbilical cable reel

- Rugged travel case

Viper Crawler System

Viper Crawler Components

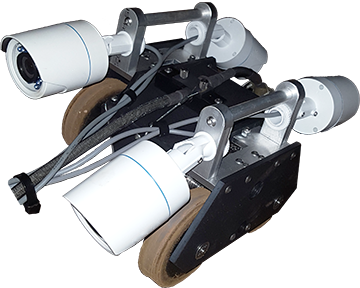

Viper Crawler System Options

The Viper Crawler can be outfitted with any combination of the following technologies:

- Supplies water to the UT Transducer for constant couplant

- Provides continuous thickness measurements

- Spring loaded flat or contoured UT shoe to match inspection surface

Ultrasound (UT)

- Detects top and bottom side surface flaws

- LFET Scanner, up to 8 channels

- Flat or contoured scanners to match inspection surface

Low Frequency Electromagnetic Technique (LFET)

- Visual inspection of pipes

- Multiple high quality cameras with bright LED lights or night vision

- Videos are stored for future review

High Quality Video

Clicking "Quote" will add the item to a temporary cart and prompt you to register/login. To view the items in this cart or send us an email requesting a quote, please complete the registration process or login.

| Description | Quantity | Add to |

|---|---|---|

| Viper Crawler System | ||

| Ultrasound(UT) Crawler | ||

| Low Frequency Electromagnetic Technique(LFET) Crawler | ||

| High Quality Video Crawler |