- The TesTex Onyx IV ECT Inspection System is based on the Eddy Current Technique (ECT) to quickly and accurately inspect non-ferrous metal tubing from the tube ID. It detects and sizes ID/OD pitting, baffle cutting, erosion, steam impingement, general wall loss, and other defects. Applications include:

- Condensers

- Feed Water Heaters

- Coolers

- Evaporators

- Chillers

- The Onyx IV can also be used to inspect ferrous materials for large flaws and small pitting. The system can distinguish between ID and OD flaws.

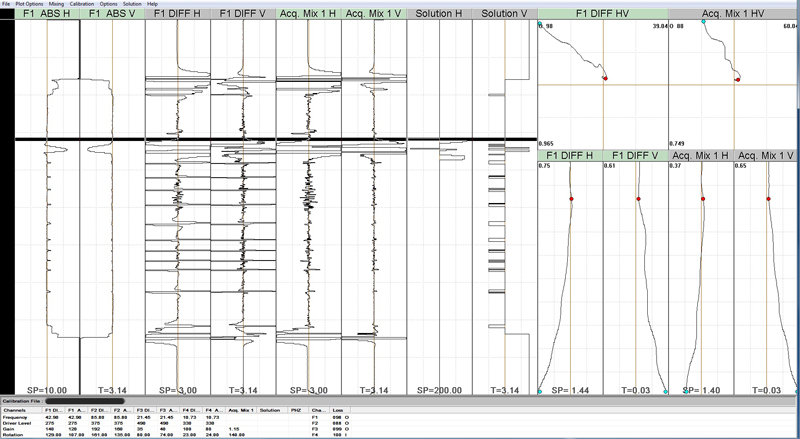

- The system has differential and absolute responses for each frequency and a built-in reference signal allowing absolute signal generation without the use of a reference probe.

- Real-time mixing is available for suppression of support/baffle plates. The system may view absolute and differential modes at the same time.

- The electronic boards are designed for independent operation to permit easier troubleshooting, repair, and expansion. Each of the main circuit boards is designed to act as a nearly complete single frequency system. More frequencies can be added to a system by inserting additional circuit boards to the backplane board.

Onyx IV ECT Inspection System

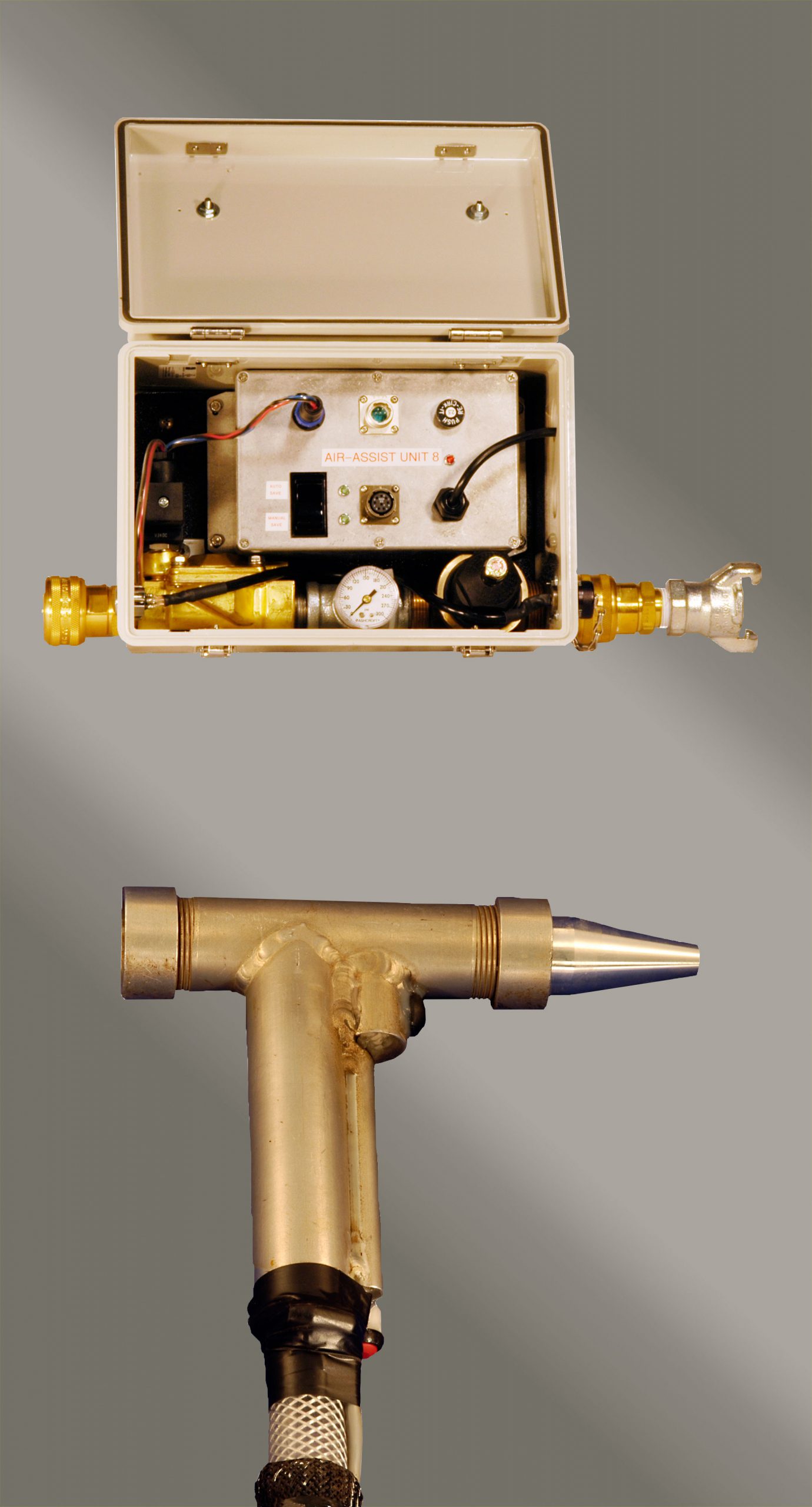

- The Onyx IV ECT Inspection System can be operated with a manual probe or one of two optional probe drivers. The PD-6k provides insertion speeds of 5ft/sec (1.52m/sec) while the PDP-22 can attain a maximum insertion speed of 20ft/sec. Whether a manual probe or optional probe driver is used, they all connect directly to the Onyx IV using the same software assuring a durable and reliable system.

- As its name implies, the PD-6k is a six kilogram (6 kg or 13.2 pound) probe driver.

- It is extremely portable and lightweight.

- It permits high-speed probe insertion, adapts to different air fittings, and needs only (regular) plant air to operate.

- With the PD-6k, it is possible to inspect up to 8 tubes per minute and 2,000 – 3,000 tubes per team per 12 hour shift.

- The PD-6k can be used with ferrous or non-ferrous metal.

Optional Probe Drivers

PD-6k

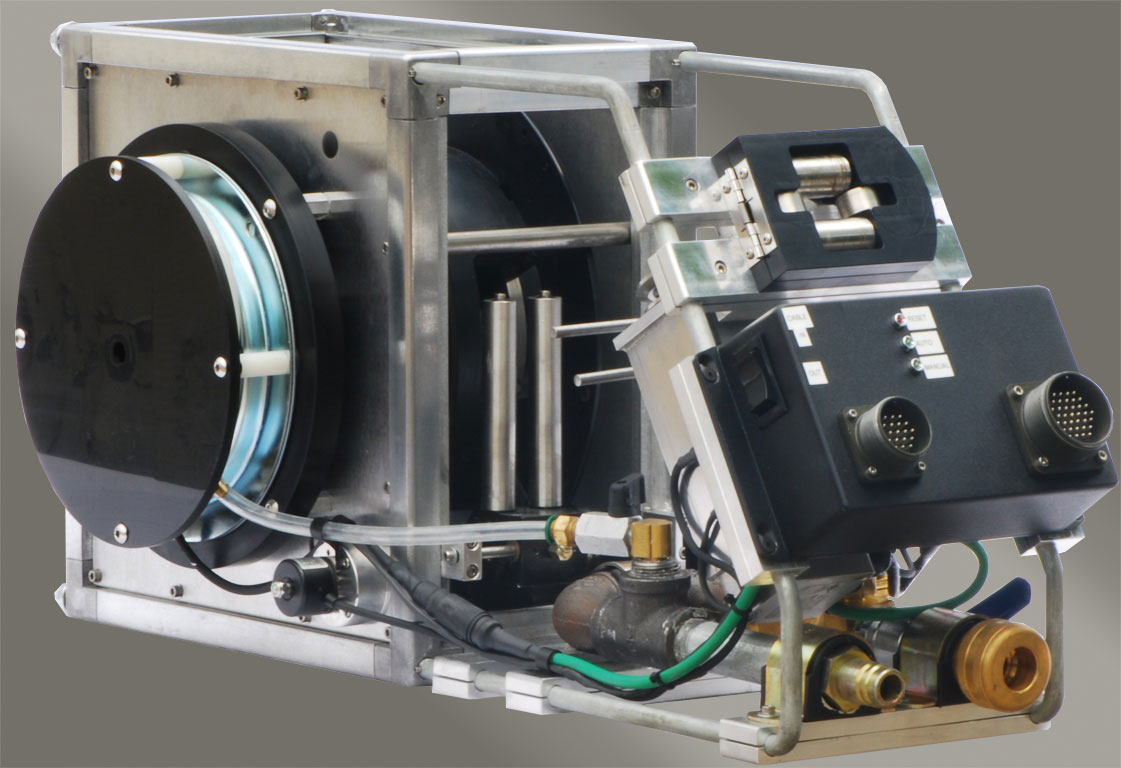

- The PDP-22 fits in 16” (406mm) manways, and permits retrieval and inspection at constant speed. Maximum insertion speeds are 20 ft/sec (6.10m/sec), and maximum inspection speeds are 10 ft/sec (3.05m/sec).

- It is “over-designed” to ensure a long operating life, and its modular components are easy to maintain and repair. It allows 110/220V operation.

- With its automated analysis, it can inspect up to twelve (12) tubes per minute, and 4,000 – 5,000 tubes per team per 12-hour shift.

PDP-22

- The Onyx IV offers eight standard channels with multiple mixing channels for better flaw sizing and detection

- 1KHz to 1.2MHz frequency range

- Fully digital offering real-time mixing and a wide variety of special data filters

- Compatible with bobbin, surface, and magnetic saturation probes

- Unwanted signals such as support plates can be suppressed

- Can be used in conjunction with our TS-Map and AR-Wizard software

- All data is archived for analysis and processing as well as comparison to future inspections

- Automated and Manual analysis done on-site.

- Ferrous tubes can be inspected using the MagWave MWET technique in conjunction with the Onyx IV

Additional Information

Clicking "Quote" will add the item to a temporary cart and prompt you to register/login. To view the items in this cart or send us an email requesting a quote, please complete the registration process or login.

| Description | Quantity | Add to |

|---|---|---|

| Onyx IV Inspection System | ||

| PD-6k Probe Driver | ||

| PDP-22 Probe Driver | ||

| High Frequecy ECT Probe | ||

| Medium Frequency ECT Probe | ||

| Low Frequency ECT Probe |