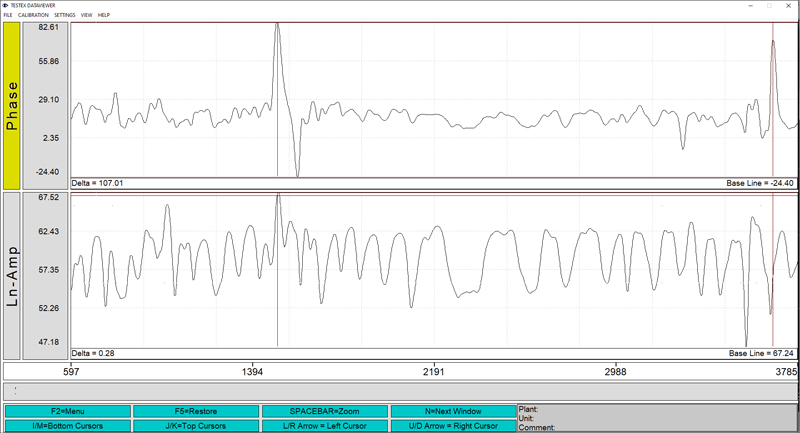

- Utilizes one to eight channels with low signal-to-noise ratio

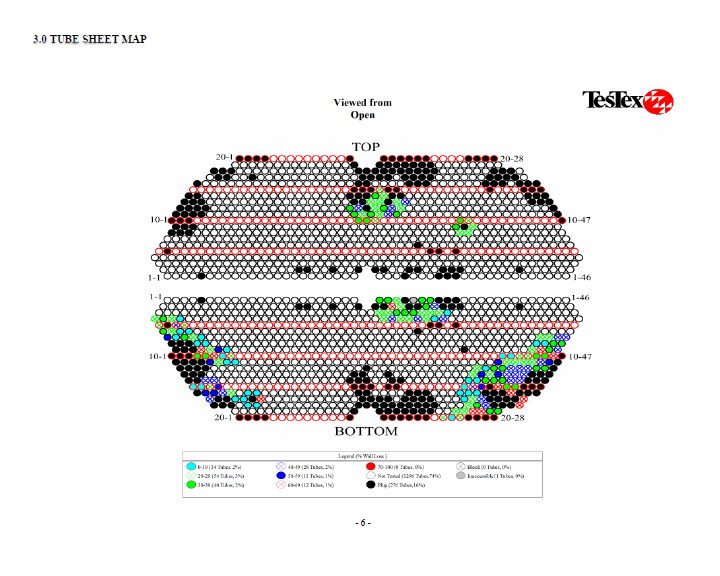

- Detects and quantifies flaws, including corrosion, erosion, pitting, cracking and metallurgical defects

- ID inspection of straight tubes, U-bends, or small diameter pipes

- Works with ferrous and non-ferrous metals

- ID or OD scale does not affect signal

- Displays high resolution, real time, 3-D color graphics of the scan results

- Results can be saved for further analysis or permanent archiving

Triton II RFET System

(Remote Field Electromagnetic Technique)

- Provides full circumferential coverage over entire length of tube or pipe

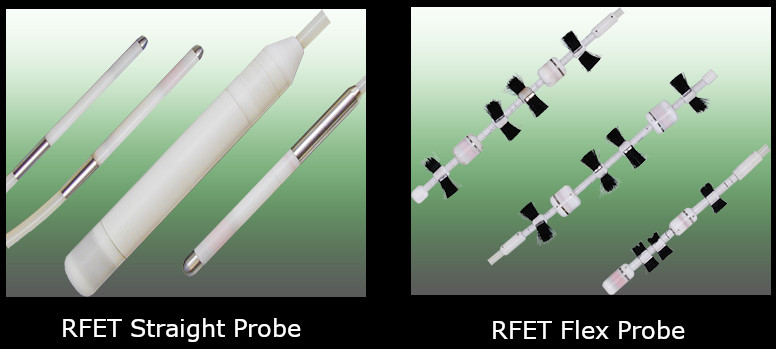

- Probe sizes from 0.21″ (8mm) to 6″ (150mm)

- Probe fill factor can be as low as 40%

- Single channel probes operate in absolute or differential modes

- Multi-channel probes allow for higher flaw resolution

- Flexible probes inspect tubes and pipes with bends

Triton II RFET System Probes

- Unlike competing products, our Triton II RFET system requires minimal surface preparation to be effective

- Faster inspection because less pre-cleaning is required. Our RFET probe does not require a high fill factor and is not affected by scale

- Operates with a wide frequency range (5Hz – 7.5kHz) allowing the system to inspect ferrous and non-ferrous materials

- 300 – 400 tubes can be inspected in a 10 – 12 hour shift

- Probe lengths up to 150 feet without signal pre-amplification

- Probes do not use permanent magnets or electromagnets

Advantages over Competing Technologies

Triton II RFET System

- For IRIS UT, surfaces need to be thoroughly cleaned

- Does not easily penetrate through oxides, scale, deposits and debris

- Slow inspection technique, 100 tubes per shift

- For MFL method, surfaces need to be thoroughly cleaned

- MFL probes need very high fill factor

- Cannot determine flaw sizes

Limitations of Competing Technologies

Internal Rotating Inspection System – Ultrasound (IRIS UT)

Magnetic Flux Leakage (MFL)

Clicking "Quote" will add the item to a temporary cart and prompt you to register/login. To view the items in this cart or send us an email requesting a quote, please complete the registration process or login.

| Description | Quantity | Add to |

|---|---|---|

| Triton II RFET System | ||

| RFET Straight Probe | ||

| RFET Flex Probe |