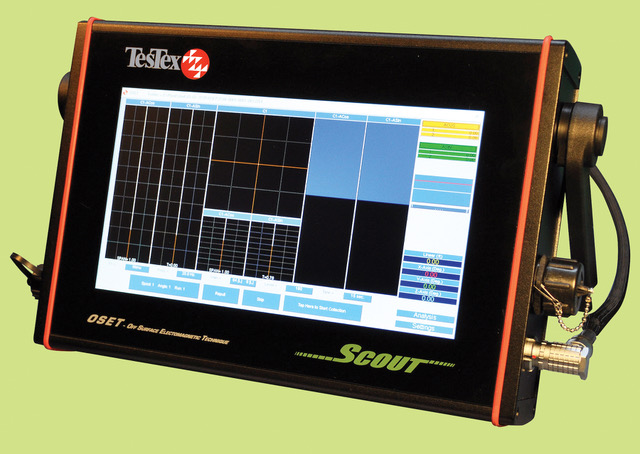

OSET Scout

- Experience TesTex’s cutting-edge solution for detecting Corrosion Under Insulation (CUI) with our proprietary Off Surface Electromagnetic Technique (OSET). Introducing the Scout system, designed to eliminate the inefficiencies of insulation stripping and random thickness checks. With Scout, you can precisely identify and address areas that demand attention, streamlining your inspection process and saving valuable time and resources. Trust TesTex for innovative solutions that redefine efficiency and accuracy in CUI detection.

Advantages and Features

- One or two-man operation

- Portable all-in-one electronics with 10.1″ (257 mm) sunlight-readable touch screen

- AC or DC power

- A True scanning technique with high throughput

- Light-weight scanner design that fits most piping, vessels, and tanks starting at 2″ (50.8 mm) diameter piping and ranging up to flat surfaces

- Scans through stainless steel and aluminum cladding with insulation thicknesses up to 3″ (76.2mm) and 4″ (102 mm) respectfully.

- Type of insulation (calcium silicate, mineral wool, fiberglass, etc.) has no effect on signal response. The presence of moisture within the insulation also has no effect

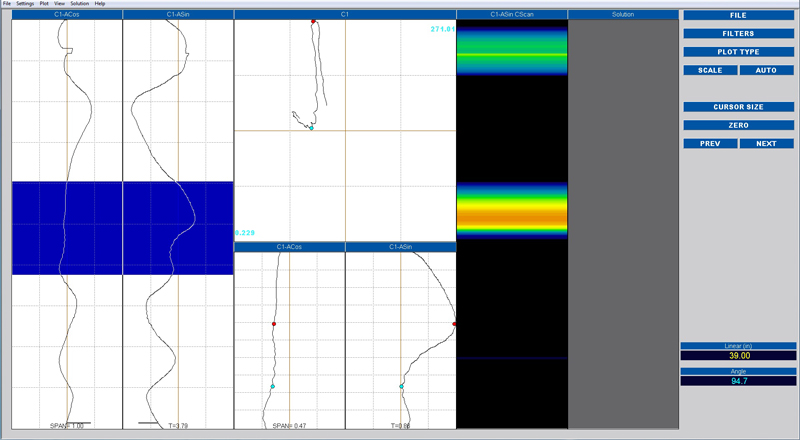

- Detects surface corrosion (wall loss, pitting) on piping of any wall thickness and large area I.D. corrosion on schedule 40 piping

- Can locate butt welds

- Encoded data with mapping option

- Multiple wheel sets and quick release pins on the axles allows the versatility of using only one scanner for your inspection needs

- Water Resistant

- Circumferential scanning technique on cladding overlaps to eliminate “reduced sensitivity/dead zones”

- Positioning device displaying circumferential position and reference angle to assure straight scans and angular position of the next scan

Detection Capabilities

| Cladding Material | Insulation Thickness | ||

|---|---|---|---|

| Wall Loss Detection | Pit Detection | Weld Detection | |

| Stainless Steel | up to 4″ | up to 3″ | up to 4″ |

| Aluminum | up to 3″ | up to 2″ | up to 3″ |

Options

- Mapping Software

- Extra batteries/chargers

- 75ft.(23m) extender cable

- Specialty calibration pipes with specified defects (a standard pit calibration pipe and a welded calibration pipe is included with the system purchase)

Previous CUI Inspection Results

| Customer | Pipe Size | Comments/Results |

|---|---|---|

| East Coast Chemical Plant | 4″ & 6″ |

|

| Mid-Western Power Plant | 4″ – 16″ |

|

| Ohio Valley Power Plant | 6″ |

|

| East Coast Chemical Plant | 2″ – 6″ |

|

Clicking "Quote" will add the item to a temporary cart and prompt you to register/login. To view the items in this cart or send us an email requesting a quote, please complete the registration process or login.

| Description | Quantity | Add to |

|---|---|---|

| OSET Scout System |