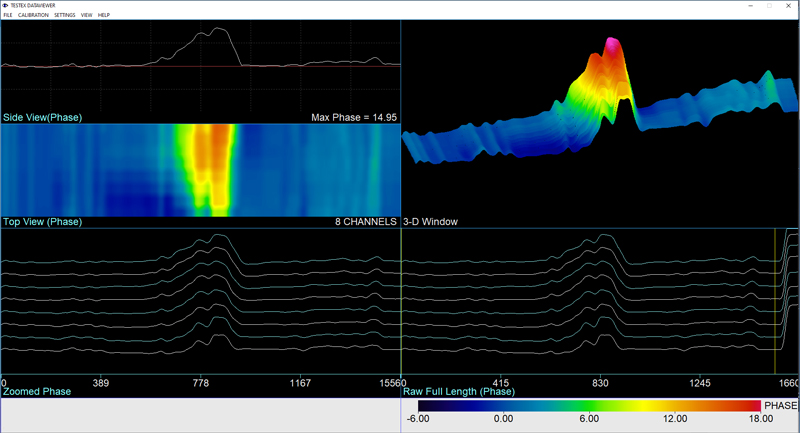

- Utilizes up to eight channels with low signal-to-noise ratio

- Detect flaws, including corrosion cells, hydrogen damage, caustic and phosphate gouging, oxygen pitting, ID pitting, corrosion, erosion and magnetite blockages

- Scans ferrous and non-ferrous materials

- Display high resolution, real time, 3-D color graphics of the scan results

- Results can be saved for further analysis or permanent archiving

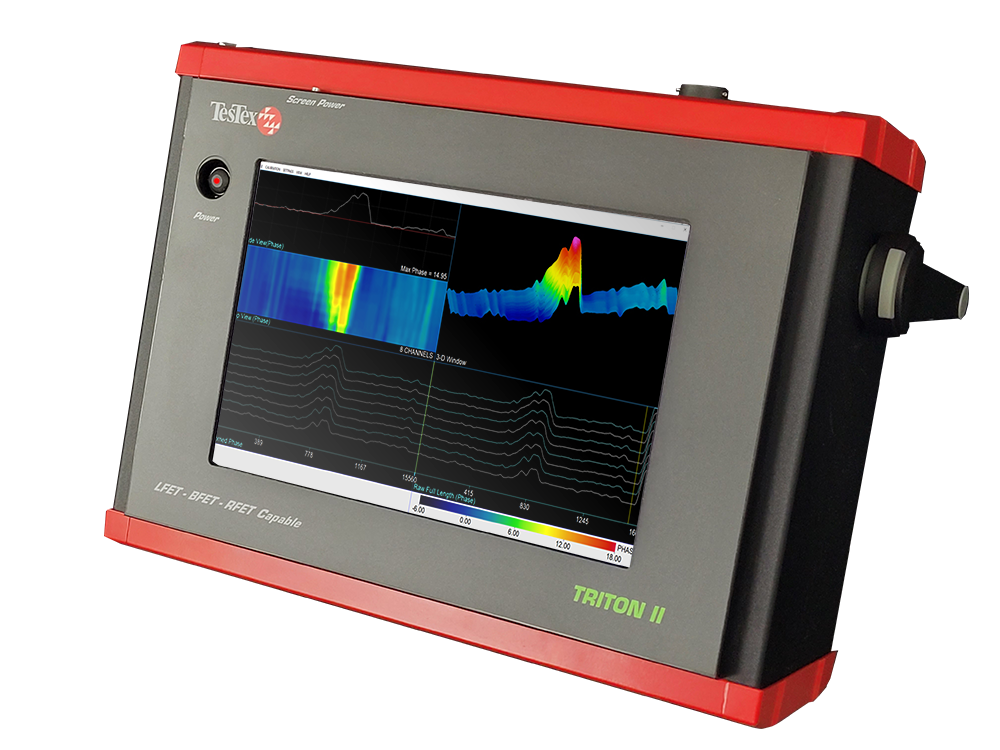

Triton II LFET System

(Low Frequency Electromagnetic Technique)

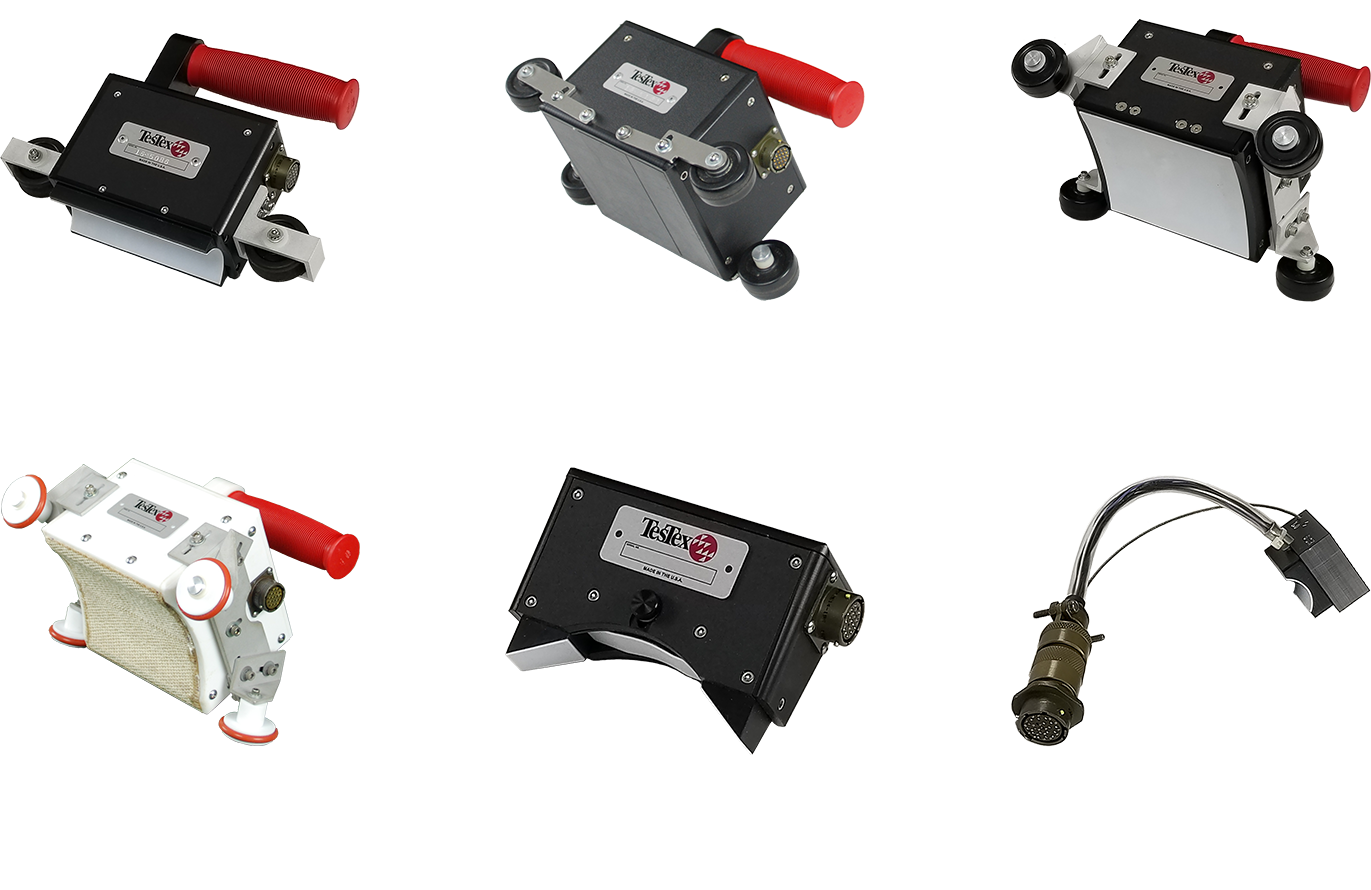

- Flat scanners can be used on plates

- Contoured to scan tubes and pipes of any diameter

- Sensors are only a few millimeters in diameter giving greater detection capabilities for smaller flaws such as pitting

- For bends, we have customized curved scanners for scanning the extrados and sides of bends

Triton II LFET Scanners

- Unlike competing products, our Triton II LFET system requires minimal surface preparation to be effective

- Efficiency is due to the fact that the our LFET scanner is a dry-contact method; the scanner surface containing the sensors does not need to touch the surface being tested

- Operates at low frequencies (usually 10Hz or lower), therefore; the electromagnetic field is not affected by any non-magnetic deposits, including iron oxide/scale

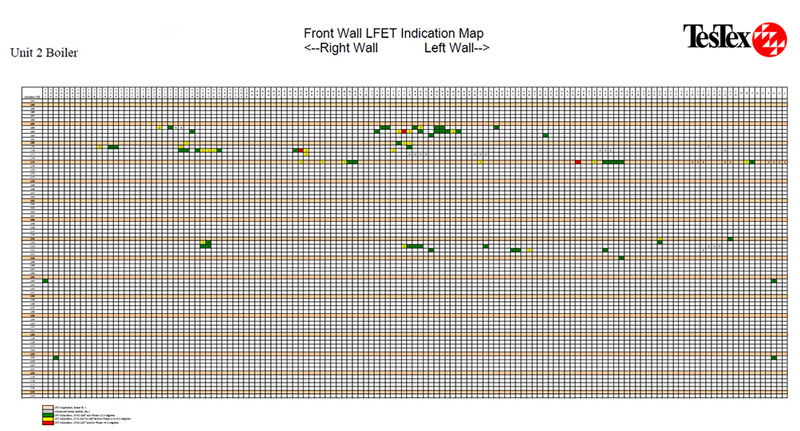

- 2,000 – 3,000 linear feet of surface material can be scanned in a 10-12 hour shift with one inspection team

- Scanning can be conducted from skyclimbers or hard scaffolding

Advantages over Competing Technologies

Triton II LFET System

- For ultrasound, surfaces need to be sandblasted, or spot-prepared for individual discreet UT thickness readings

- Does not provide rapid scanning coverage; UT merely involves spot checks

- For the EMAT method, surfaces need to be sandblasted

- The EMAT method does not provide rapid scanning coverage, EMAT only scans a strip less than one-quarter-inch (¼″) wide

- X-Ray methods have inherent limitations because access is required on two sides of the sample. There are also restrictions to the surrounding area of the sample being tested

Limitations of Competing Technologies

Ultrasound (UT)

Electromagnetic Acoustic Transducer (EMAT)

X-Ray (RT) / Radiography

Clicking "Quote" will add the item to a temporary cart and prompt you to register/login. To view the items in this cart or send us an email requesting a quote, please complete the registration process or login.

| Description | Quantity | Add to |

|---|---|---|

| Triton II LFET System | ||

| Tube Scanner | ||

| Flat Scanner | ||

| Pipe Scanner | ||

| High Temperature Scanner | ||

| Adjustable Scanner | ||

| Low Profile Scanner |