- Tank floor scanner based on Saturation Low Frequency Eddy Current Technique

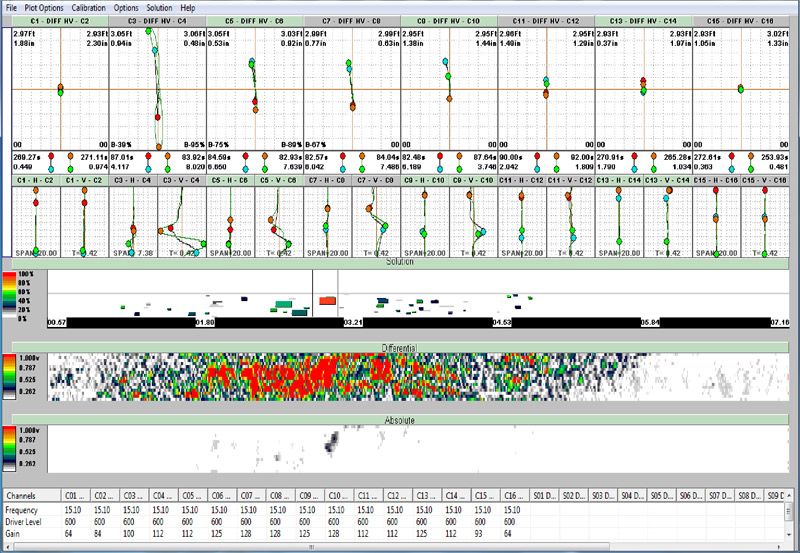

- Operates by saturating floor plates with an electromagnet and then scanning for defects using Eddy Current Technique (ECT)

- The Falcon S Series is able to detect pits, holes, cracking and wall loss

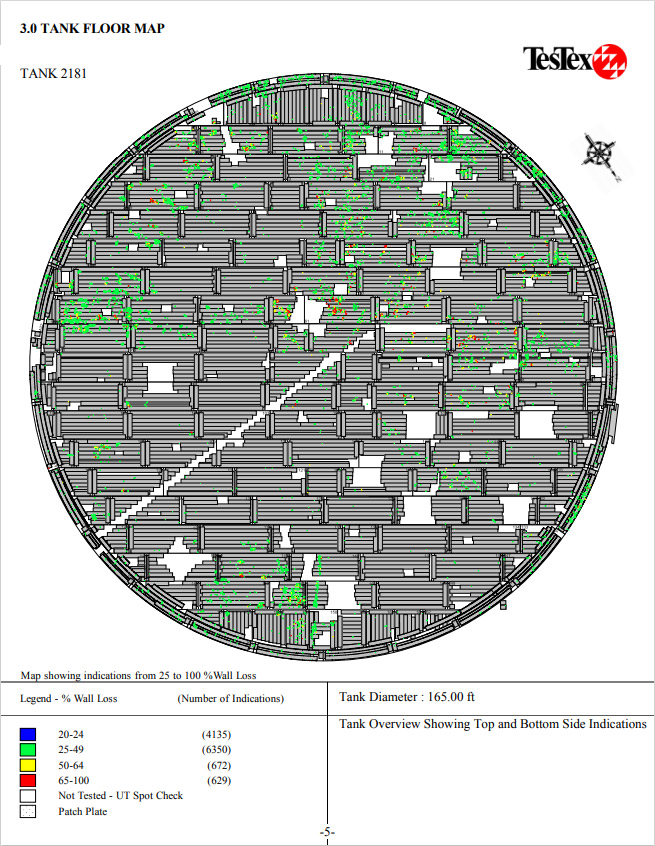

- Flaws can be differentiated by orientation depending on if they are located on the top or bottom side

- The Falcon S Series represents the latest in tank floor scanning technology

Falcon S Series

- The Falcon S Series uses similar technology to our MagWave system, in that it brings Eddy Current accuracy to ferrous plates.

- The highly sensitive nature of ECT allows the scanner to detect and size top side and bottom side pitting, as well as localized wall loss. Additionally, the Falcon S Series can detect cracks.

- The Falcon S Series is able to scan through non-metallic coatings up to 0.5in. (12mm) thick.

Differences from other Falcon products

- Self propelled with adjustable scanning speeds

- Scanning path 14in. (355mm)

- 16 channel array for high resolution scans

- Penetration of 1.2in. (30mm)

- Scans through a maximum of 0.5in (12 mm) thick non-metallic coatings

- Built in encoders

Tank Floor Scanner

- Designed to scan hard to reach places

- Scanning path 5in. (127mm)

- 4 channel array

- Penetration depth of 0.75in. (190mm)

- Scans through a maximum of 0.35in (9mm)thick non-metallic coatings

Hand Scanner

Clicking "Quote" will add the item to a temporary cart and prompt you to register/login. To view the items in this cart or send us an email requesting a quote, please complete the registration process or login.

| Description | Quantity | Add to |

|---|---|---|

| Falcon S Series System |