What if you could get a better picture of your HRSG Tube to Header Welds?

- The Tube to Header welds in HRSG’s are a common failure item, but they have some unique challenges when it comes to inspecting them. Mag particle and dye penetrant seem to be the common method of inspection giving approximately 180 degrees of coverage in the front of the first row of tubes. In a four row configuration that only affords you a 12.5% inspection rate. In a three row configuration its 16.6%. Is that really enough to make a determination on a plan of action to maintain your HRSG? Would you feel more confident with a 25% – 66% inspection? How much more value would that add to the inspection report?

TesTex BFET Claw Inspection

Inspection of HRSG Tube to Header Weld

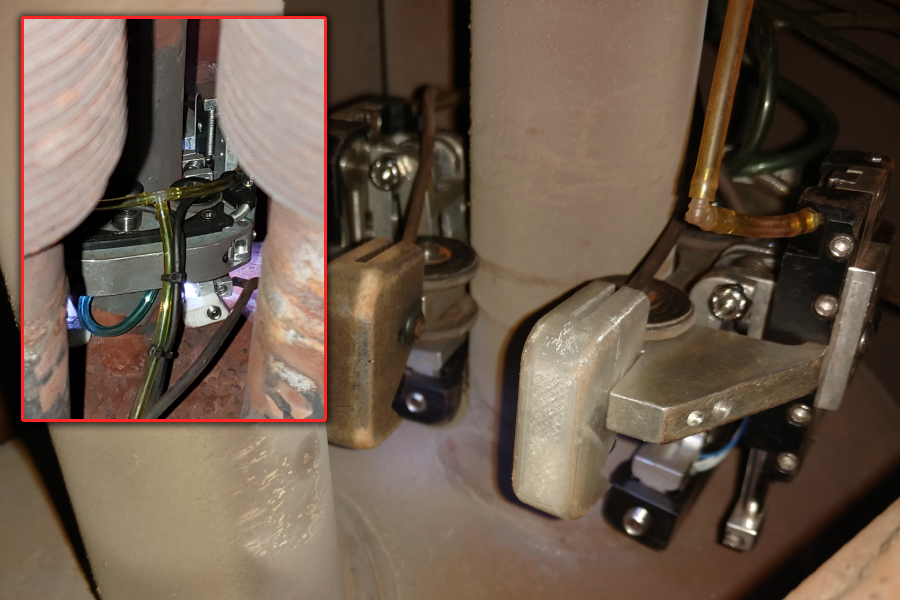

- We adapted the Balanced Field Electromagnetic Technique (BFET) to inspect the tube to header welds in HRSG units for cracking. The BFET sensors and cameras are placed on the welds using a C-clamp housing called the “Claw” that attaches to the tube. This modular design means 360% coverage on each tube to header weld; its small size can allow for inspection of the second row of tubes in most cases.

- Once attached, the Claw moves circumferentially around the weld to detect cracking, lack of fusion, porosity and other weld defects

- No surface preparation is needed to perform the Claw inspection

- The Claw can detect indications down to 0.200” below the test surface

- A two man team can examine up to 200 tube to header welds in a shift

- Used for inspection of tube diameters from 1.5″ (38mm) to 3″ (76.2mm)

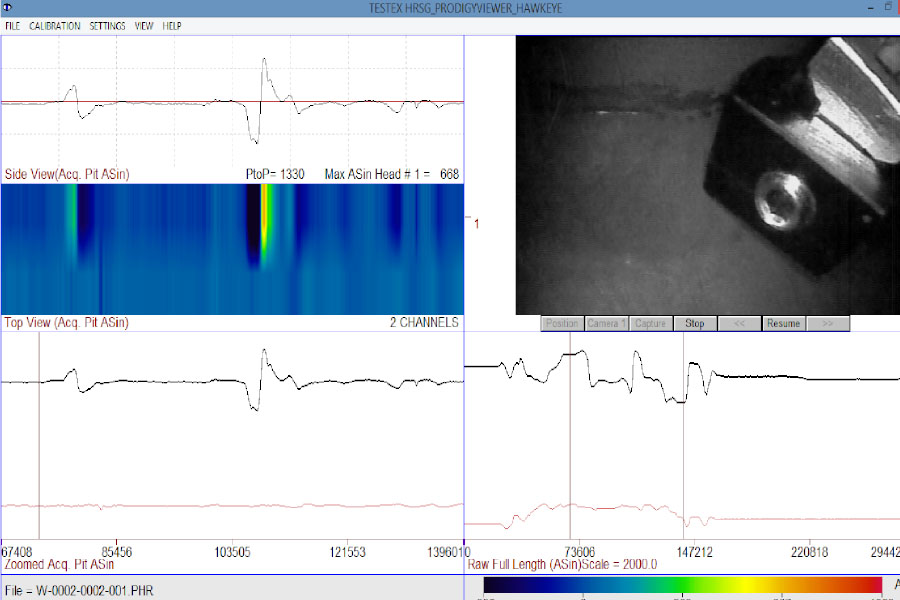

- Cameras are used to show contour of weld to help in analyzing the BFET data

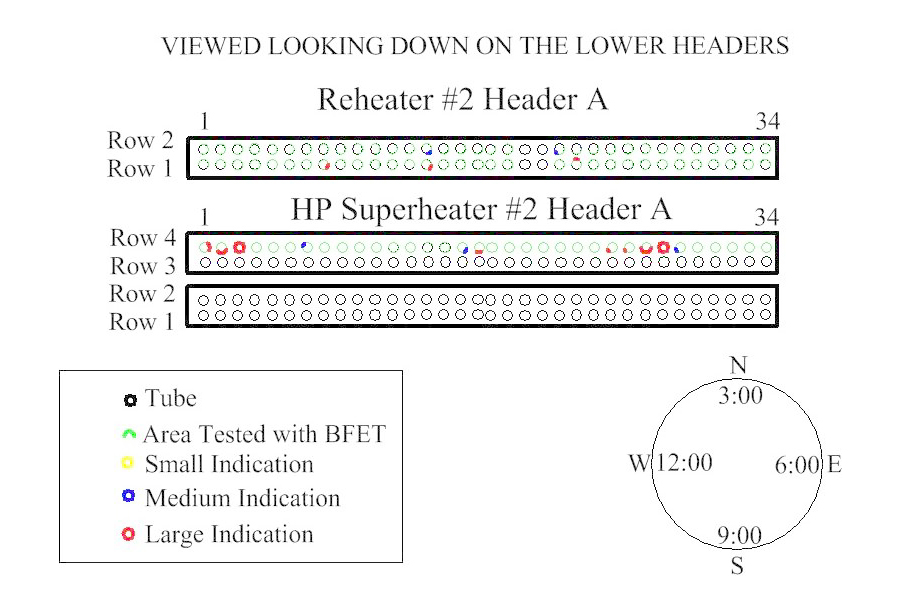

What the claw has found so far:

- This image is from a report of one of the many inspections the Claw has been used in. The image clearly indicates several locations where medium and major flaw indications were detected. Several of these flaws would be impossible for mag particle and dye penetrant to be used effectively.

The Claw Device

- The TesTex Claw device is designed to latch on to the tube and be rotated by hand or for tubes in the second row there is an attachment to allow you to rotate it from a distance. TesTex developed this tool in house with our Solution’s Provider Group. Not only do we provide inspection services but we also sell the equipment in case you have your own inspection team.

- The large image shows a close up of the Claw, the inset shows the Mini-Claw inspecting the second row of tube welds in a header.

Previous Work sites:

| Customer | Inspection | OEM |

|---|---|---|

| AMP | HPSH1 and RH1 | Nooter |

| NRG | ||

| PPL | Hanjung | |

| PEPCO | ATS/Express LLC | |

| Xcel | Nooter | |

| NRG | #1 HRSG & #2 HRSG | |

| PEPCO | ATS/Express LLC | |

| Southern Company | Deltak | |

| Southern Company | Vogt | |

| TVA | Foster Wheeler | |

| Dynegy | #1 HRSG Sec Superheater | Aalborg |

| Avangrid Renewables | Toshiba | |

| 1st Energy | ||

| Irving Oil | HP, SH, HP Econ | Aalborg |

| Dominion | #2 FW Heater Section | Nooter |

| AMP | #2 HRSG | Nooter |

| AEP | Reheat 1 | Nooter |

| Alliant | #1 HRSG #2 HRSG | Nooter |

| AMP | Nooter | |

| Southern Company | RH #3 | |

| FPL | ||

| Blythe Energy | IP Evaperator | Vogt |

| Victory Energy/Siouxland Ethanol | Victory Energy | |

| Calpine | Reheater #3 | IHI |

| OG&E | Secondary Superheater | Zurn |

| Cogentrix | Vogt | |

| NRG | #6 HRSG #8 HRSG | NEM |

| FPL | #8 HRSG | NEM |

| So Cal Edison | HRSGs 4A & 4B / HRSGs 3A & 3B | Foster Wheeler |

| Duke Energy | HP SH | Nooter |

| Santee Cooper | Reheater | |

| Calpine | RH3 |

Clicking "Quote" will add the item to a temporary cart and prompt you to register/login. To view the items in this cart or send us an email requesting a quote, please complete the registration process or login.

| Description | Quantity | Add to |

|---|---|---|

| Claw Inspection System | ||

| Claw HRSG Inspection Service |