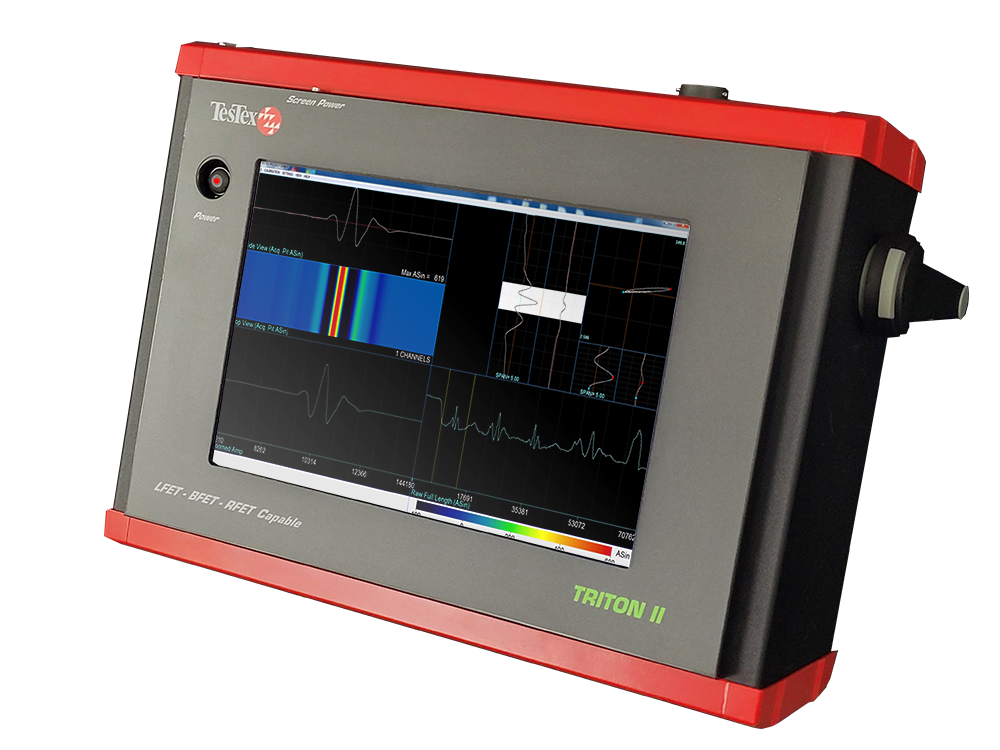

Triton II BFET System

(Balanced Field Electromagnetic Technique)

- Detects both surface and sub-surface cracks in welds and base metals

- Minimum surface preparation

- No couplant required

- Scanning speed up to 1 ft/sec

- Able to scan through paints and coatings

- Displays high resolution, real time, 3-D color graphics of the scan results

- Results can be saved for further analysis or permanent archiving

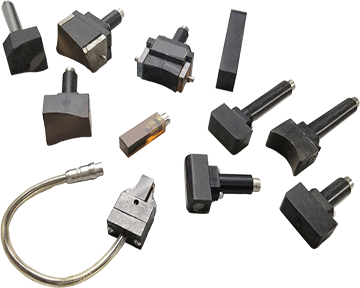

Triton II BFET Probes and Scanners

- Customized to fit any application and weld profile

- Curved, flat or welded surfaces can be quickly evaluated even through paints and coatings

- Multi-Channel array scanner provides high resolution imaging and real-time display of flaws

- ID scanners detect internal cracking of tubes and pipes

- Claw Scanner detects cracks in HRSG Tube-to-Header welds

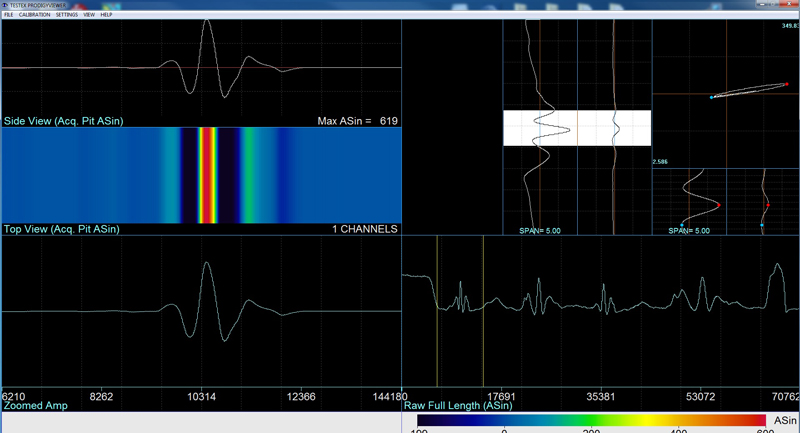

BFET waveform of stress cracking scanned with exterior scanner

BFET waveform of stress cracking scanned with exterior scannerTriton II BFET System Additional Information

- Used anywhere cracking is an issue, including both ferrous and nonferrous metals

- Signal processing eliminates liftoff and noise signals

- Supports single and multi-channel scanners up to 8 channels

- Multi-Channel scanners give real-time high resolution imaging of flaws

- Detects flaws within 1/8″ of surface or 3/8″ with deep penetrating scanner

- Scans welds of similar and dissimilar metals

Clicking "Quote" will add the item to a temporary cart and prompt you to register/login. To view the items in this cart or send us an email requesting a quote, please complete the registration process or login.

| Description | Quantity | Add to |

|---|---|---|

| Triton II BFET System | ||

| BFET Probes and Scanners |