Inspection Update: Detecting IGA and SCC with LFET

A June 2025 inspection applied the Low Frequency Electromagnetic Technique (LFET) to evaluate 128 stainless steel boiler pendants for intergranular attack (IGA) and stress corrosion cracking (SCC). Results showed a rise in flaw signals in one section of tubing compared to the previous inspection in October 2024, while other sections showed only minor changes. These findings highlight LFET’s effectiveness in trending subtle changes in boiler tube integrity over time.

Inspection History and Validation

To date, Boiler 4 has undergone three inspections (January 2024, October 2024, and June 2025). A parallel UT survey is conducted at each outage, and the combined data sets provide a strong assessment of failure risk. Cut tubes identified by LFET indications have been confirmed by the plant’s metallurgy lab to exhibit SCC, validating the technique’s accuracy in pinpointing problem areas.

Material Background

The site operates four boilers. Boilers 3 and 4 were built with SS304 tubing and Inconel overlay as a temporary solution during the supply shortages caused by the COVID pandemic and the Ukraine-Russia conflict, when SS347 could not be sourced. Boilers 1 and 2, built with SS347 stainless steel, have not experienced SCC issues. Boiler 3 has only shown minor signs of SCC, while Boiler 4 continues to display more severe cracking activity. Plant personnel suspect that sulfur infiltration into the water system could be contributing to Boiler 4’s accelerated SCC, though this has not yet been verified.

Causes of IGA and SCC

IGA and SCC are driven by a combination of susceptible alloys, corrosive agents, moisture, and stress. At elevated temperatures, chromium migration in stainless steels like 304 can form carbides at grain boundaries, reducing corrosion resistance. Corrosive salts such as NaOH—often introduced through condenser leaks or resin breakdown—are a common trigger, and once deposited, they are difficult to remove. Moisture during offline periods and residual stresses further accelerate crack initiation and growth.

Inspection Findings

LFET identified flaw signals consistent with SCC, most visible as fluctuations in waveform output. Wall thinning was observed in some pendants, with thicknesses reduced to .140–.150 in. compared to the expected .170–.180 in. Several circuits registered high-phase responses classified as significant flaws, while tube replacements remained in good condition with no evidence of corrosion.

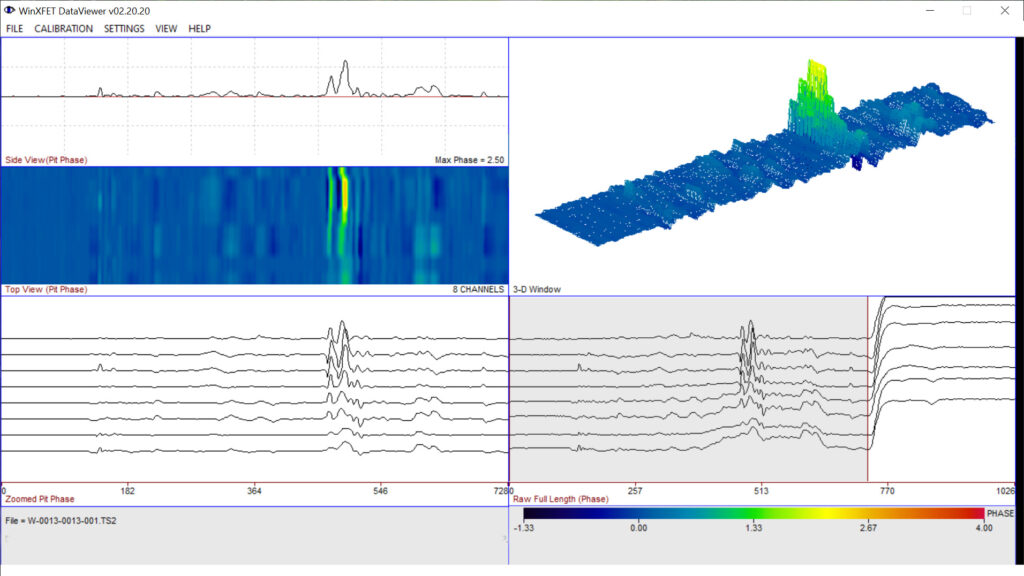

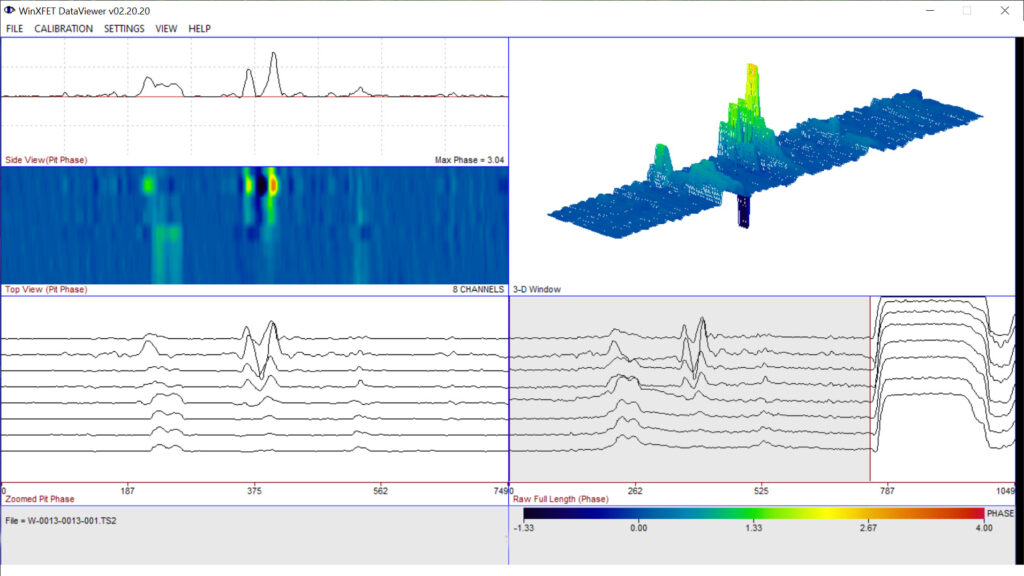

Waveform Analysis

Waveform comparisons with past inspections confirmed both stable and advancing flaw signatures across multiple circuits. Fluctuating signals in particular marked early crack activity and progression of IGA.

Field Data

Next Steps and Advancements

The team is also test-running fusion scanners during the current Boiler 3 inspection. Early results show a 2–3x increase in phase response, which will improve sensitivity in catching SCC at earlier stages. This advancement, coupled with LFET’s proven ability to trend flaws over time, represents a strong step forward in proactive monitoring and long-term boiler reliability planning.

If you would like to learn more about our inspections, our systems, or how they can be used on your site, please contact us at 412.798.8990 or click here.