Hawkeye Crack Detection

Problem

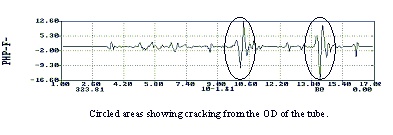

A prominent, high volume manufacturing company in Montana was experiencing generating bank tube failures due to cracking in one area of their Riley Stoker Hog Fuel boiler. This unit had been operating under increased steam production, causing low steam drum water levels therefore affecting the upper portion of the tubes.> After submitting a failed tube sample to a metallurgical lab, it was determined that the cracks were most likely due to thermal fatigue initiating on the exterior/OD of the tube.

The problem was determining if there were any other signs of surface cracking near the steam drum area using a technology that was fast, accurate and needing minimal tube preparations.

Traditional methods such as mag particle and dye penetrant were not an option due to time constraints and the uncertainty of how much surface prep would be needed to get accurate results.

Solution

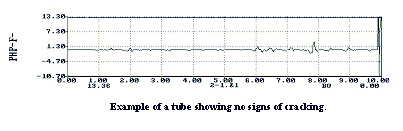

While on-site for full-length boiler tube inspection, TesTex crews deployed the firm’s Hawkeye 2000 Scanning System to identify any cracks in the suspect areas that included a 40-inch area from the steam drum to just below the steam drum bend in the first row of the generating bank tubes.By using a single channel probe and scanning along the outside length of the tube, TesTex was able to identify fifteen tubes that showed indications of surface and sub-surface cracking.

These tubes were cut-out and replaced so that the unit could be put back on line.

After further analysis of the removed tubes, TesTex found surface cracking that was not visible to the eye.

TesTex’ inspection helped the customer focus on the replacement/dutchman effort to get back on line with minimal down time. The original intent of the customer was to replace all tubes in the first row. This would have prolonged the outage for three days and cost additional money and down time.

Conslusion

There are many variables that come into play as to how long it will take for a crack to go “thru-wall.” Therefore, it is difficult to predict how long it takes for a crack to initiate on a given tube. With the help of the customer taking steps to identify the problem prior to the inspection, TesTex was able to establish a useful means of flaw detection by using the Hawkeye 2000 Scanning System.The ability to scan up to 1 ft/sec without a couplant, makes using the Hawkeye 2000 Scanning System ideal to locate cracking. For more information on the Hawkeye 2000 Scanning System or other TesTex products and services, please contact us or call 412.798.8990.

Field Data