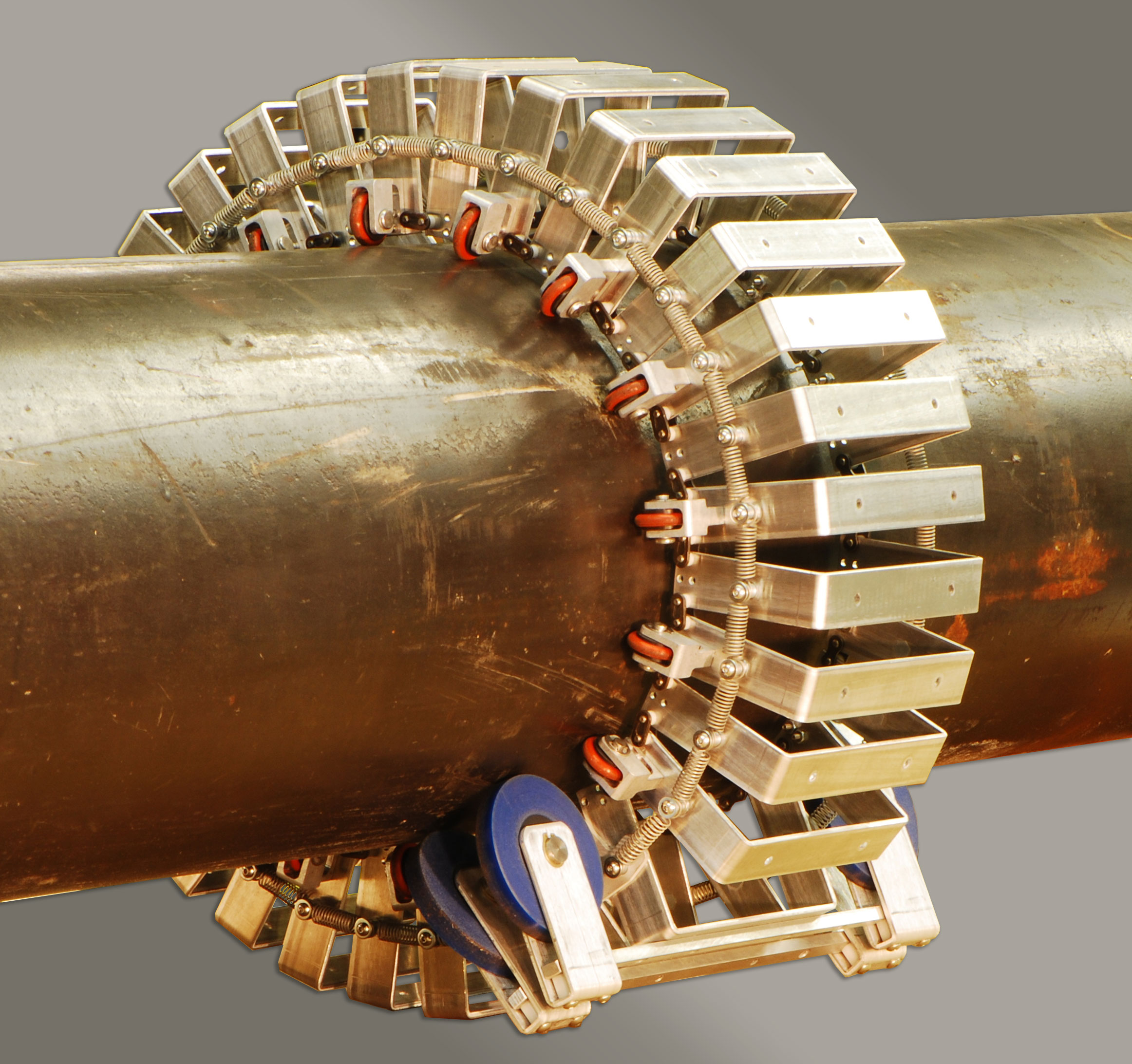

- Using the Low Frequency Electromagnetic Technique (LFET), the lightweight, aluminum, TesTex Line CAT quickly scans from the outer diameter to detect both ID and OD gradual wall loss, pitting, gouging, and other defects of ferrous and non-ferrous pipes.

- The modular design of the Line CAT allows the system to be quickly modified for pipe sizes starting at 3” in diameter. For pipes less than 10” in diameter, the Line CAT performs 360° scanning. For larger pipes, it scans 120°, or 1/3 of the circumference on each pass. Additionally, the Line CAT can be outfitted with an encoder.

- The TesTex Line CAT can be propelled by an optional remote-controlled, magnetic wheeled “crawler,” which is capable of traveling up to ten (10) ft/min.

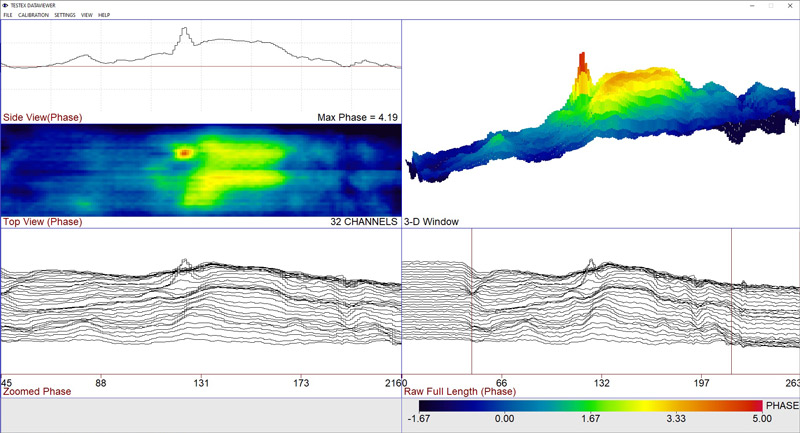

- The Line CAT’s contoured top shell supports and stabilizes the main sensor array. The sensor array is made up of many scanning pods that contour to the actual geometry of the pipe via a flexible coupling system. The Line CAT can travel around bends and over welds, and all components can operate in arctic conditions down to -40° Fahrenheit. It scans through uniform scale, rust, or coatings. Scan results are shown on a high-resolution 3-D graphics display.

Line CAT

- The Line CAT system was field tested on two sections of insulated crude transit pipelines on the Alaska North Slope. The insulation was removed from both pipelines. One pipeline had anti-corrosion tape, while the other was bare. These sections were tested with three different techniques: (1) the Electromagnetic Acoustic Transducer Technique (EMAT), (2) Automated Ultrasonic Thickness (A.U.T.), and (3) our LFET via a Line CAT system.

- Although A.U.T was able to give actual thickness readings, it had a very slow scan rate. EMAT displayed scan rates faster than the A.U.T., but the Line CAT was by far the most productive. Both EMAT and LFET demonstrated a 100% POD (probability of detection) for 25% wall loss isolated pitting at a 3:1 aspect ratio.

- EMAT displayed a reduction in the scan rate over the tape-covered section, from 1,000 ft per day on uncoated piping to 500 ft per day on tape-coated piping. The scan rate of LFET remained unchanged over the tape-coated piping (approximately 10 ft/min). Also, LFET has a false positive over call rate of less than one percent (1%). The field test clearly showed that the Line CAT was the most efficient method and had the highest overall productivity for the job.

Field Application

Clicking "Quote" will add the item to a temporary cart and prompt you to register/login. To view the items in this cart or send us an email requesting a quote, please complete the registration process or login.

| Description | Quantity | Add to |

|---|---|---|

| Line CAT System |