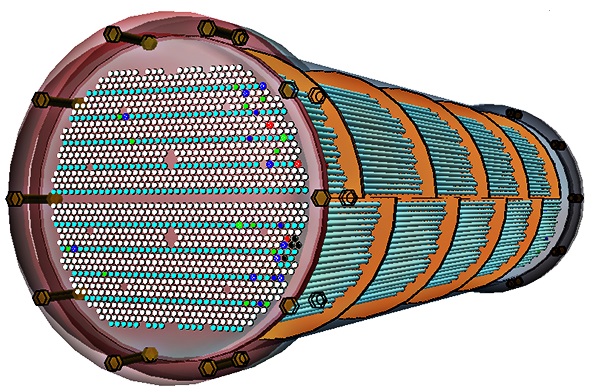

- TesTex is your go-to provider for comprehensive inspection services for all types of tubular heat exchangers, including air cooler fin fans. What sets us apart from other NDT companies is our expertise and specialization in heat exchanger inspection. We not only perform inspections but also manufacture the equipment used in the process. With a dedicated team of 40 highly-trained field service crews, we are ready to respond promptly to your immediate inspection needs. Trust TesTex for reliable and professional heat exchanger inspections.

Heat Exchanger Inspection

TesTex offers specialized inspection solutions for different types of metals. Our Triton II RFET System is deployed for carbon steel and other magnetic metals, conducting inspections from the tube ID. For non-magnetic metals like stainless steels, copper nickels, brass, or titanium, we deploy the Onyx IV Multi-frequency/Multichannel Eddy Current System. With our tailored systems, we ensure accurate and efficient inspections for various metal types. Trust TesTex for reliable and comprehensive metal inspections.

- At TesTex, we take full control of our inspection equipment by manufacturing our own Remote Field Electromagnetic Technique (RFET) and Eddy Current Technique (ECT) systems. This enables us to meet the demands of large-scale projects, as we have the necessary test equipment readily available. Moreover, we ensure uninterrupted workflow by equipping each inspection team with ample back-up and redundant equipment. What sets us apart is our ability to respond swiftly to emergency needs. By manufacturing our own probes and calibration standards, we possess the flexibility to address urgent requirements more effectively than any other heat exchanger inspection company. Trust TesTex for reliable solutions backed by our commitment to quality and responsiveness.

- In addition to the inspections based on our RFET and ECT equipment, we also provide IRIS Ultrasonic tube inspection and video borescoping services.

- Whether you have one heat exchanger or several hundred, we have the capability to perform an inspection.

- Inspects straight sections; U-Bends can be tested with special probes

- A team can inspect 300 – 400 hex tubes in a ten-hour shift using RFET

- A team can inspect more than 400 hex tubes in a ten-hour shift using ECT

- TesTex can field 40 tubing inspection crews at any given time

- Our technicians are equipped with multiple probe sizes and back-up equipment

- RFET inspections do not require extensive tube cleaning and often are conducted with no tube preparation at all

- Can inspect tube sizes from one-half inch (OD) and greater

- Detects and sizes corrosion, erosion, pitting and baffle cutting

Clicking "Quote" will add the item to a temporary cart and prompt you to register/login. To view the items in this cart or send us an email requesting a quote, please complete the registration process or login.

| Description | Quantity | Add to |

|---|---|---|

| Heat Exchanger Inspection Services | ||

| Triton II RFET System | ||

| Onyx IV Inspection System | ||

| Helix-XT IRIS System |